Base Year Value ()

CAGR ()

Forecast Year Value ()

Historical Data Period

Largest Region

Forecast Period

Mercado de bloques de carbono de microporos por tipo (tamaño de poro promedio de 0,3 µm a 0,5 µm, el tamaño de poro promedio es inferior a 0,3 µm), por aplicación (alto horno, tanque de decapado, baño de galvanoplastia, otros) y región, tendencias globales y pronóstico de 2023 a 2030

Instant access to hundreds of data points and trends

- Market estimates from 2014-2029

- Competitive analysis, industry segmentation, financial benchmarks

- Incorporates SWOT, Porter's Five Forces and risk management frameworks

- PDF report or online database with Word, Excel and PowerPoint export options

- 100% money back guarantee

Descripción general del mercado de bloques de carbono con microporos

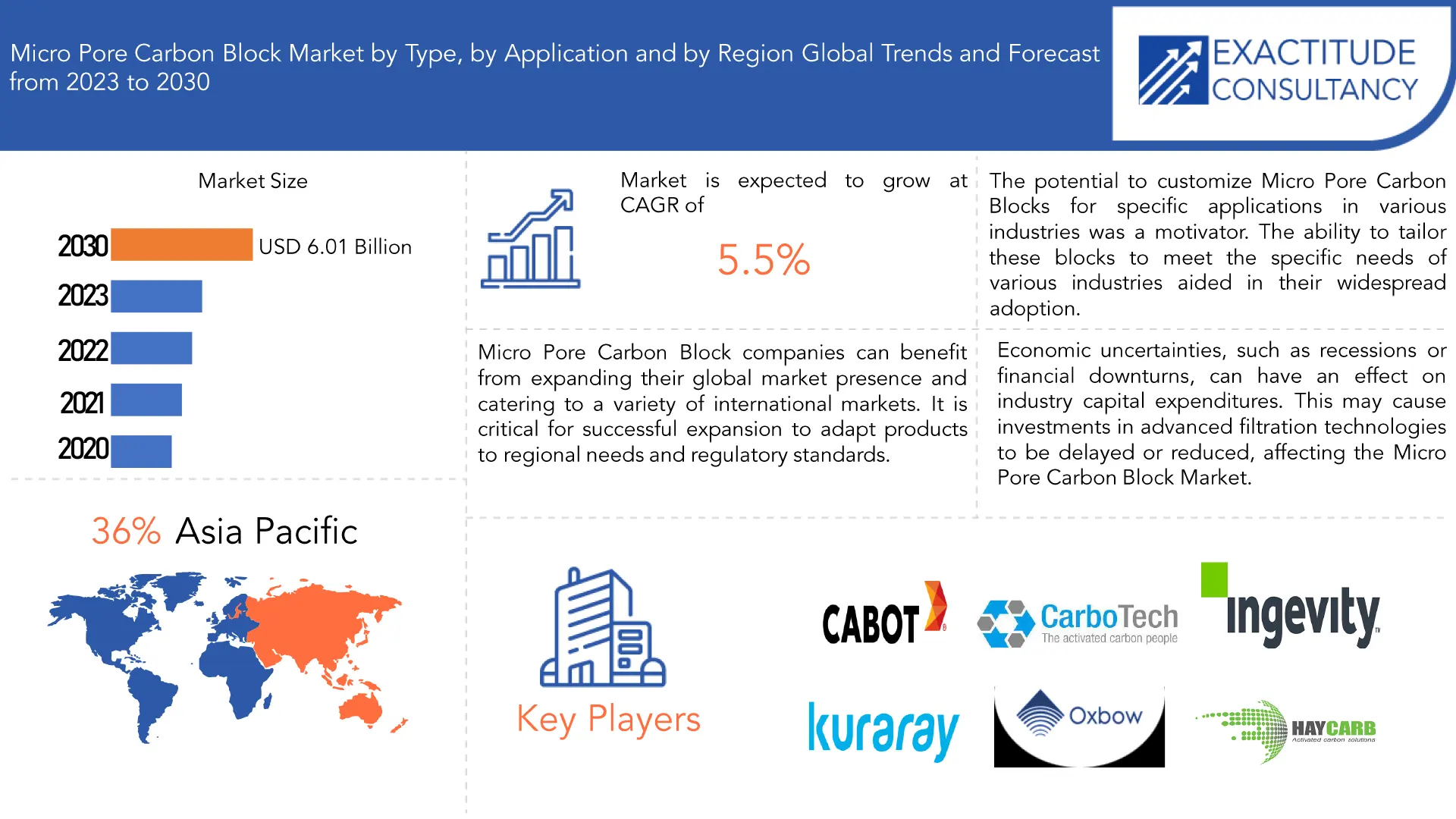

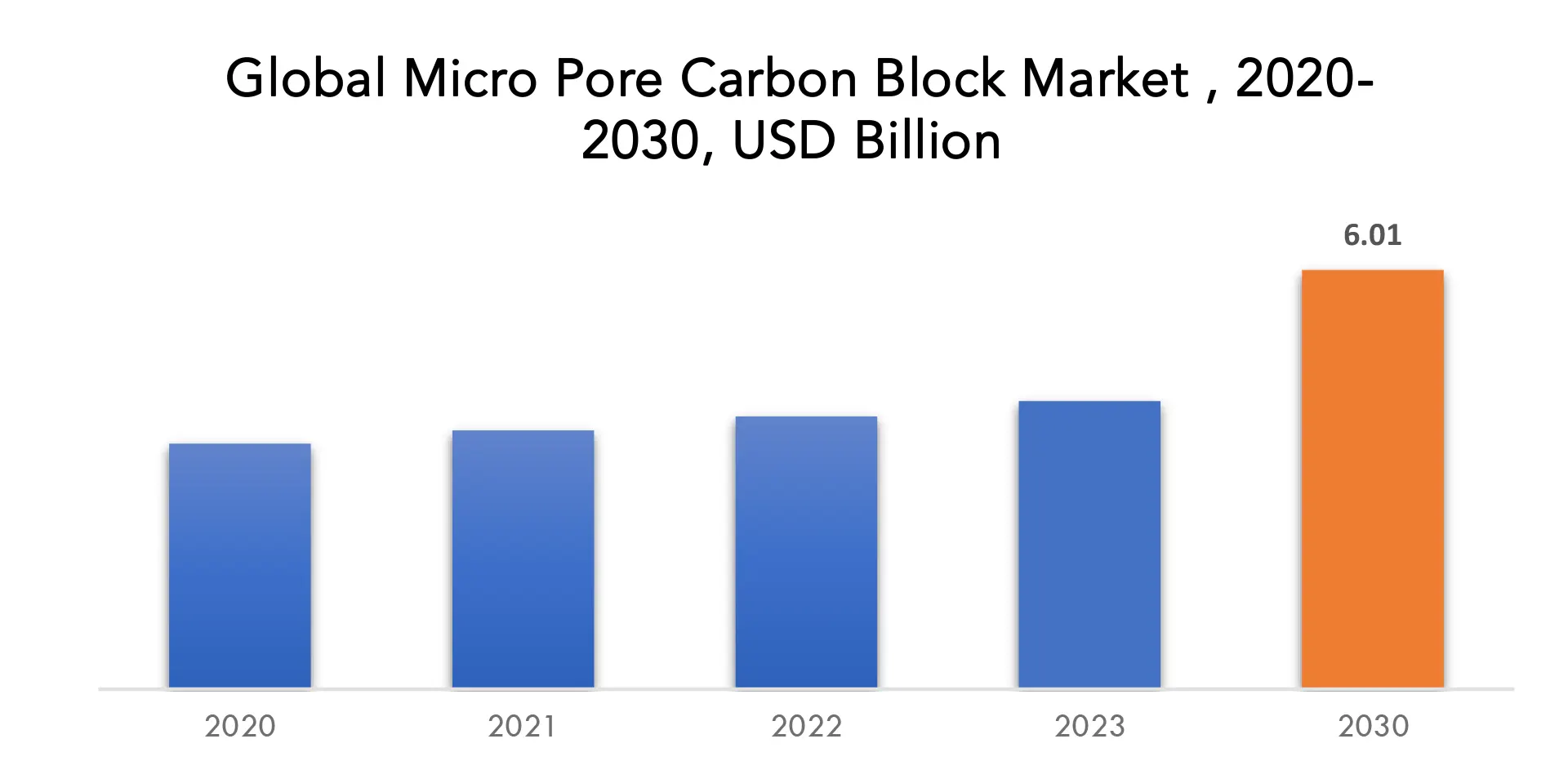

Se prevé que el mercado mundial de bloques de carbono con microporos crezca de USD 4,13 mil millones en 2023 a USD 6,01 mil millones en 2030, a una CAGR del 5,5 % durante el período de pronóstico.

Un bloque de carbón con microporos es un tipo de material de carbón que se distingue por su estructura de poros diminutos, con poros individuales que miden en micrómetros. Debido a la extensa red de poros pequeños, este bloque de carbón tiene una superficie extremadamente grande. La estructura de microporos de estos bloques de carbón mejora sus capacidades de adsorción y filtración, lo que los hace adecuados para una variedad de aplicaciones en industrias como el tratamiento de agua, la purificación de gases y el procesamiento químico.

Los pequeños tamaños de poro permiten una excelente captura de moléculas, partículas o impurezas, lo que ayuda en la purificación y filtración de líquidos y gases. Los bloques de carbón de microporos se utilizan con frecuencia en entornos donde se requiere un control preciso sobre la eliminación de contaminantes, y su versatilidad se extiende a aplicaciones como sistemas de purificación de aire y agua, soporte de catálisis y fabricación de productos químicos especiales. Las propiedades únicas de los bloques de carbón de microporos los hacen valiosos en procesos que requieren alta pureza, capacidad de adsorción y estabilidad química.

[título id="attachment_31608" align="aligncenter" width="1920"]

El mercado de los bloques de carbón microporosos es importante debido a su papel fundamental para satisfacer la creciente demanda de filtración y purificación precisas en diversas industrias. El bloque de carbón microporoso, con su estructura de poros microscópicos, proporciona una solución única y altamente efectiva para eliminar impurezas, contaminantes y contaminantes de líquidos y gases. Esta tecnología es especialmente útil en el tratamiento del agua, donde ayuda a producir agua potable más limpia y segura al adsorber eficazmente toxinas y partículas.

Additionally, the Micro-Pore Carbon Block's high surface area and selective adsorption properties improve the quality and purity of end products in industrial processes such as gas purification and chemical manufacturing. The market's significance is further highlighted by its application in critical sectors such as healthcare, where it helps to create sterile environments, and environmental protection efforts to reduce air and water pollution. As industries continue to prioritize environmental sustainability and stringent quality standards, the Micro-Pore Carbon Block market serves as a linchpin, providing advanced filtration solutions that contribute to cleaner, safer, and more efficient industrial processes worldwide.

| ATTRIBUTE | DETAILS |

| Study period | 2020-2030 |

| Base year | 2022 |

| Estimated year | 2023 |

| Forecasted year | 2023-2030 |

| Historical period | 2019-2021 |

| Unit | Value (USD Billion) Volume (Thousand Units) |

| Segmentation | By Type, Application and Region |

| By Type |

|

| By Application |

|

| By Region |

|

Frequently Asked Questions

• What is the market size for the Micro Pore Carbon Block market?

The global Micro Pore Carbon Block market is expected to grow from USD 4.13 Billion in 2023 to USD 6.01 Billion by 2030, at a CAGR of 5.5 % during the forecast period.

• Which region is dominating in the Micro Pore Carbon Block market?

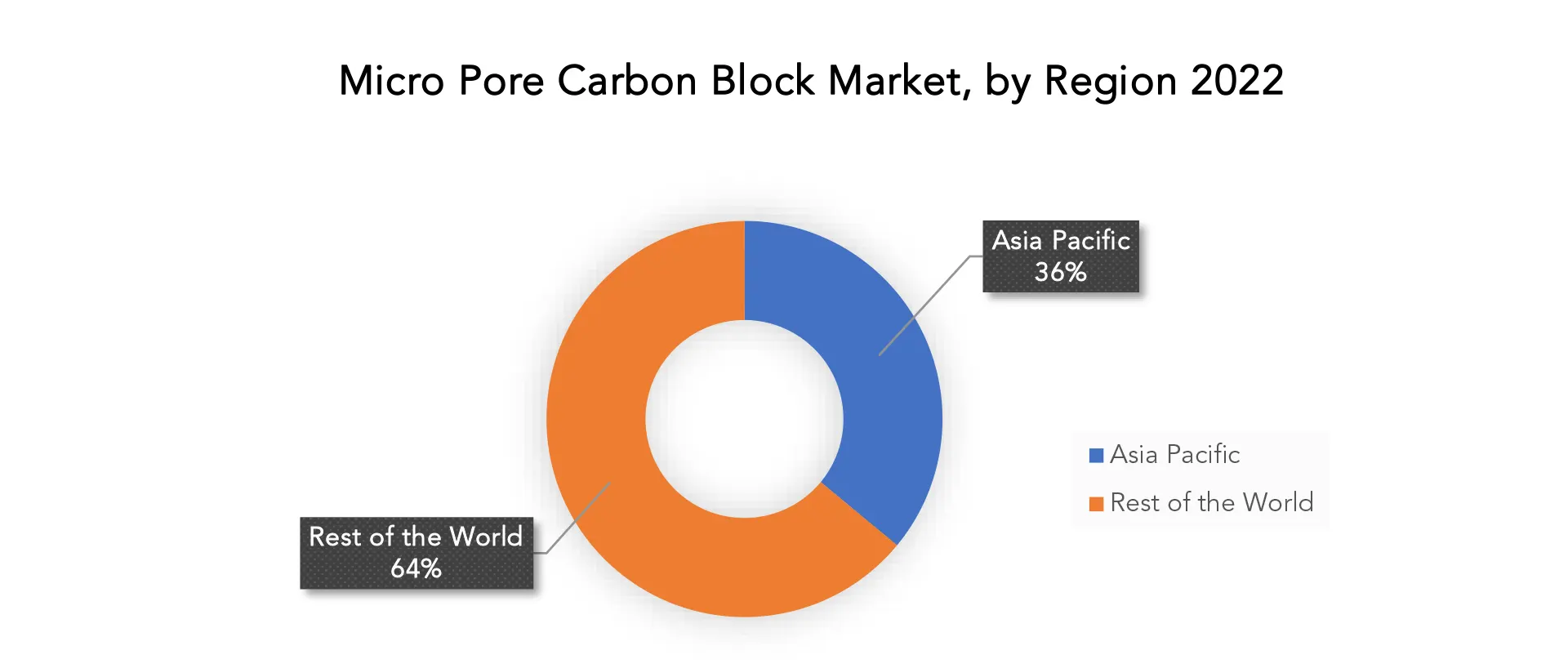

Asia Pacific accounted for the largest market in the Micro Pore Carbon Block market. North America accounted for 36% market share of the global market value.

• Who are the major key players in the Micro Pore Carbon Block market?

Kuraray Co., Ltd, Cabot Corporation, Calgon Carbon Corporation, Haycarb PLC, Osaka Gas Chemicals Co., Ltd, Carbon Activated Corporation, ADA Carbon Solutions, CECA, Donau Carbon Corporation, Ingevity Corporation, Clarimex Group, Activated Carbon Technologies, Carbon Link Corporation, Carbon Resources LLC, Westwater Enterprises, A.L. Filter, CarboTech AC GmbH, Oxbow Activated Carbon.

• What are the key trends in the Micro Pore Carbon Block market?

A growing emphasis was placed on expanding market presence in developing economies. As industries in these regions expanded, there was a greater demand for advanced filtration solutions, which presented opportunities for Micro Pore Carbon Block manufacturers.

Micro Pore Carbon Block Market Segmentation Analysis

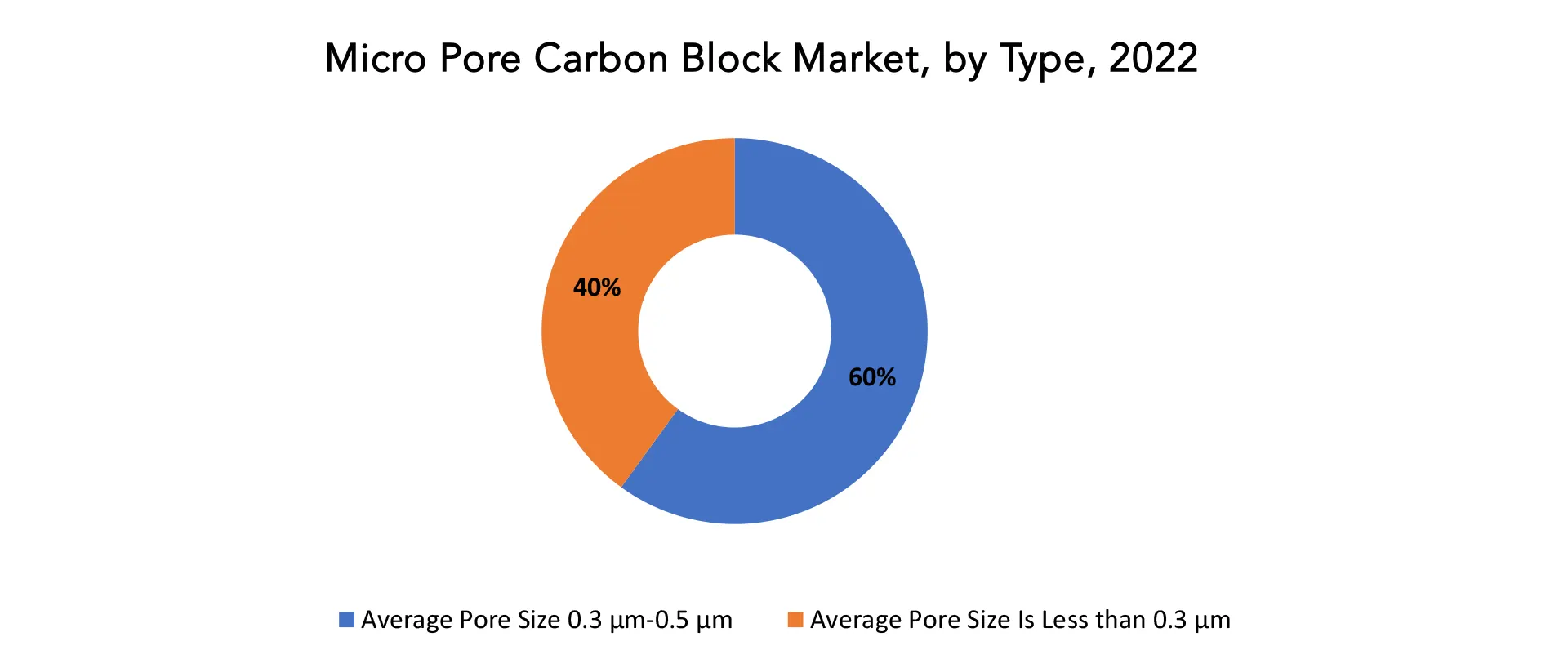

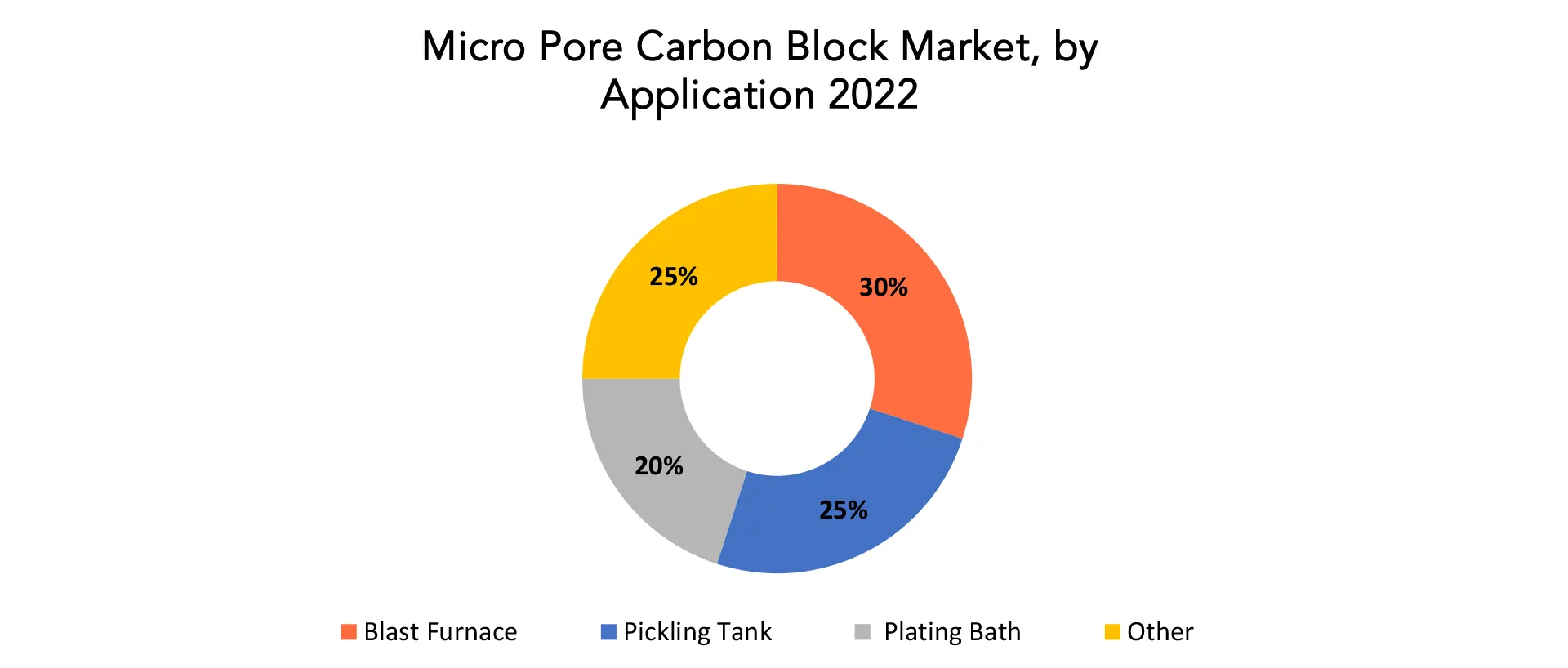

The global micro pore carbon block market is divided into three segments, type, application and region. By type, the market is divided into Average Pore Size 0.3 µm-0.5 µm, Average Pore Size Is Less than 0.3 µm. By application the market is classified into blast furnace, pickling tank, plating bath, other and by region.

[caption id="attachment_31630" align="aligncenter" width="1920"]

Based on type, the market is divided into average pore size 0.3 µm-0.5 µm, average pore size is less than 0.3 µm. This section contains Micro-Pore Carbon Blocks with pore sizes ranging from 0.3 to 0.5 micrometers on average. This pore size range of carbon blocks is intended to provide a specific level of filtration efficiency. Pores of this size capture particles and impurities of a specific size, making them suitable for applications requiring fine filtration. This category of products may find use in industries such as water purification, air filtration, or any process that requires precise control over the size of filtered particles.

Micro-Pore Carbon Blocks with an average pore size of less than 0.3 micrometers are included in this category. Smaller pore size carbon blocks are designed for even finer filtration. They can capture smaller particles and contaminants, resulting in a more pure filtered product. This segment may find applications in industries requiring extremely high levels of filtration, such as pharmaceutical manufacturing, semiconductor manufacturing, or any process where maintaining a pristine environment is critical.

[caption id="attachment_31633" align="aligncenter" width="1920"]

Based on application, the market is divided into blast furnace, pickling tank, plating bath, other. This segment includes Micro-Pore Carbon Blocks, which are specifically designed for use in blast furnaces. Blast furnaces are critical components in the steelmaking process, as they are where raw materials are melted and transformed into molten iron. Carbon blocks used in blast furnaces must be able to withstand high temperatures and harsh conditions. The percentage assigned to this segment represents the proportion of Micro-Pore Carbon Blocks designed for blast furnace applications in relation to the total market.

In metal processing, pickling tanks are used to remove impurities and scale from the surface of metals. Micro-Pore Carbon Blocks for Pickling Tank Applications would be designed to withstand corrosive environments while effectively filtering out contaminants. This segment's percentage denotes the proportion of Micro-Pore Carbon Blocks intended for use in pickling tanks. In electroplating processes, plating baths are used to apply a thin layer of metal to a substrate. Carbon blocks used in plating baths must be corrosion resistant while also remaining chemically stable. The portion of Micro-Pore Carbon Blocks optimized for plating bath applications is represented by the percentage allotted to this segment. The "Other" category includes applications besides blast furnaces, pickling tanks, and plating baths. This could include a variety of industrial processes where Micro-Pore Carbon Blocks are used because of their unique properties, such as high-temperature resistance, chemical inertness, and effective filtration capabilities. This percentage represents the collective share of Micro-Pore Carbon Blocks in various applications.

[caption id="attachment_31634" align="aligncenter" width="1920"]

Micro Pore Carbon Block Market Dynamics

DriverThe increasing demand for water purification has become a global priority as concerns about water quality and safety rise in market.

As concerns about water quality and safety grow, the increasing demand for water purification has become a global priority. With a growing population and expanding urbanization, ensuring access to clean and safe drinking water has become a critical necessity. In response to this pressing need, advanced water purification technologies have seen a significant increase in demand. Micro Pore Carbon Blocks, with their intricate microscopic pore structure, play an important role in water treatment systems. These carbon blocks excel at effectively removing a wide range of contaminants and impurities from water sources, including organic compounds, chlorine, volatile organic compounds (VOCs), and other pollutants. The carbon blocks microscopic pores act as highly efficient filters, trapping and adsorbing impurities to produce purified water. This feature not only improves the taste and odor of water, but also ensures its safety for consumption. As governments, communities, and businesses around the world strive to meet stringent water quality standards, the use of Micro Pore Carbon Blocks in water treatment processes has become critical. The continued rise in demand for clean water, fueled by environmental concerns and regulatory mandates, propels the Micro Pore Carbon Block market forward, establishing it as a key player in the global water purification landscape.

RestraintCost factor hampers the growth in Micro pore carbon block market.

Manufacturing of Micro Pore Carbon Blocks is a technologically advanced process that requires the use of specialized materials and intricate manufacturing techniques. These blocks are designed with a microscopic pore structure, giving them unique filtration capabilities. However, the complexity of the manufacturing process and the requirement for specific high-quality materials contribute to relatively higher production costs. This cost factor becomes a significant constraint, especially for industries and applications operating on tight budgets. The advanced technologies and materials required for Micro Pore Carbon Blocks frequently result in higher production costs, making the product more expensive when compared to traditional filtration alternatives. As a result, industries that prioritize cost-effectiveness may find it difficult to implement Micro Pore Carbon Blocks. Despite their exceptional performance in targeted applications, this constraint poses a barrier to widespread adoption of these advanced filtration solutions. Manufacturers and stakeholders in the Micro Pore Carbon Block market must address these cost factors strategically, perhaps through advancements in manufacturing techniques or economies of scale, to improve affordability and market accessibility.

OpportunitiesThe increasing global demand for clean and safe drinking water presents a significant opportunity for Micro-Pore Carbon Blocks.

The growing global demand for clean and safe drinking water has increased the importance of Micro-Pore Carbon Blocks, which provide a significant opportunity in the field of water treatment and purification. With increasing pollution and contamination threats to water sources, there is an urgent need for advanced technologies that can effectively address water quality concerns. Micro-Pore Carbon Blocks, distinguished by their microscopic pore structure, excel in this domain by providing an efficient filtration solution. These blocks are capable of adsorbing and removing a wide range of contaminants such as organic compounds, chemicals, and particulate matter, ensuring that water treatment systems produce water that meets stringent safety and quality standards. Micro-Pore Carbon Blocks, whether integrated into point-of-use water filters or larger-scale municipal treatment plants, contribute significantly to impurity removal, resulting in clean, clear, and safe drinking water. Because of their adaptability, these blocks are critical in the global effort to ensure access to safe drinking water, addressing a critical need for public health and environmental sustainability. As concerns about water quality grow, the Micro-Pore Carbon Block's role in water treatment highlights an important opportunity to meet the world's growing demand for dependable and advanced water purification solutions.

Micro Pore Carbon Block Market Trends

- The growing global concern about water quality and the growing need for safe drinking water were driving a significant demand for Micro Pore Carbon Blocks in water treatment applications. This trend was especially noticeable in both residential water filters and municipal water treatment systems.

- Continuous material and manufacturing technology advancements improved the performance of Micro Pore Carbon Blocks. To improve filtration efficiency and durability, manufacturers were experimenting with new manufacturing methods and the incorporation of advanced materials.

- There was a trend toward customizing Micro Pore Carbon Blocks to meet the specific needs of various industries and applications. By customizing these blocks for use in a variety of industries, including pharmaceuticals, food and beverage, and industrial processes, a broader market reach was achieved.

- In the market, sustainability was becoming a more important factor. Manufacturers were looking into environmentally friendly materials and manufacturing processes, in line with the global push for environmentally responsible solutions in water treatment and other applications.

- The use of Micro Pore Carbon Blocks in conjunction with smart technologies such as Internet of Things (IoT) connectivity was on the rise. Real-time monitoring of filtration systems, predictive maintenance, and data-driven insights into water quality were all possible as a result.

- Manufacturers were investigating global market expansion opportunities. The demand for dependable water purification solutions was not limited to specific regions, prompting businesses to explore and cater to diverse international markets.

- Aside from water treatment, there was a growing trend in the use of Micro Pore Carbon Blocks for air filtration. These blocks were used in HVAC systems, industrial air purifiers, and other applications to capture and remove airborne pollutants.

- Stringent water quality regulations and standards were influencing the market. The need for strict compliance drove the adoption of advanced filtration technologies, such as Micro Pore Carbon Blocks, in water treatment infrastructure.

Competitive Landscape

The competitive landscape of the Micro Pore Carbon Block market was dynamic, with several prominent companies competing to provide innovative and advanced Micro Pore Carbon Block solutions.

- Kuraray Co., Ltd

- Cabot Corporation

- Calgon Carbon Corporation

- Haycarb PLC

- Osaka Gas Chemicals Co., Ltd

- Carbon Activated Corporation

- ADA Carbon Solutions

- CECA

- Donau Carbon Corporation

- Ingevity Corporation

- Clarimex Group

- Activated Carbon Technologies

- Carbon Link Corporation

- Carbon Resources LLC

- Westwater Enterprises

- L. Filter

- CarboTech AC GmbH

- Oxbow Activated Carbon

Regional Analysis

North America, particularly the United States and Canada, has emerged as a dominant region, owing to strict environmental policies and a strong emphasis on clean water and air standards. Europe has also been a significant market for Micro Pore Carbon Blocks due to its advanced industrial base and commitment to sustainability. Countries in Asia-Pacific, such as China and Japan, have contributed to the market's expansion through increased industrialization and increased awareness of environmental issues. The dominant region in the Micro Pore Carbon Block Market is often defined by a combination of factors, such as a high concentration of industries requiring advanced filtration solutions, a favorable regulatory environment promoting environmental sustainability, and a robust infrastructure for filtration technology research and development. Furthermore, regions with a greater awareness of water and air quality issues, as well as a willingness to invest in advanced filtration solutions, tend to dominate the market.

Latest market analyses, industry reports, and market intelligence studies that provide insights into regional market shares and growth trends are recommended for the most up-to-date information on the Micro Pore Carbon Block Market's dominant region.

[caption id="attachment_31638" align="aligncenter" width="1920"]

Target Audience for Micro Pore Carbon Block Market

- Water Treatment Companies

- Air Purification System Manufacturers

- Environmental Engineering Firms

- Chemical and Pharmaceutical Industries

- Healthcare Institutions

- Wastewater Treatment Plants

- Industrial Manufacturing

- Research and Development Centers

- Government Regulatory Bodies

- Investors and Venture Capitalists

- End Users

Import & Export Data for Micro Pore Carbon Block Market

Exactitude consultancy provides import and export data for the recent years. It also offers insights on production and consumption volume of the product. Understanding the import and export data is pivotal for any player in the Micro Pore Carbon Block market. This knowledge equips businesses with strategic advantages, such as:- Identifying emerging markets with untapped potential.

- Adapting supply chain strategies to optimize cost-efficiency and market responsiveness.

- Navigating competition by assessing major players' trade dynamics.

Segments Covered in the Micro Pore Carbon Block Market Report

Micro Pore Carbon Block Market by Type- Average Pore Size 0.3 µm-0.5 µm

- Average Pore Size Is Less than 0.3 µm

- Blast Furnace

- Pickling Tank

- Plating Bath

- Other

- North America

- Europe

- Asia Pacific

- South America

- Middle East and Africa

Key Question Answered

- What is the expected growth rate of the Micro Pore Carbon Block market over the next 7 years?

- Who are the major players in the Micro Pore Carbon Block market and what is their market share?

- What are the end-user industries driving market demand and what is their outlook?

- What are the opportunities for growth in emerging markets such as Asia-Pacific, the middle east, and Africa?

- How is the economic environment affecting the Micro Pore Carbon Block market, including factors such as interest rates, inflation, and exchange rates?

- What is the expected impact of government policies and regulations on the Micro Pore Carbon Block market?

- What is the current and forecasted size and growth rate of the global Micro Pore Carbon Block market?

- What are the key drivers of growth in the Micro Pore Carbon Block market?

- Who are the major players in the market and what is their market share?

- What are the distribution channels and supply chain dynamics in the Micro Pore Carbon Block market?

- What are the technological advancements and innovations in the Micro Pore Carbon Block market and their impact on product development and growth?

- What are the regulatory considerations and their impact on the market?

- What are the challenges faced by players in the Micro Pore Carbon Block market and how are they addressing these challenges?

- What are the opportunities for growth and expansion in the Micro Pore Carbon Block market?

- What are the product offerings and specifications of leading players in the market?

- INTRODUCTION

- MARKET DEFINITION

- MARKET SEGMENTATION

- RESEARCH TIMELINES

- ASSUMPTIONS AND LIMITATIONS

- RESEARCH METHODOLOGY

- DATA MINING

- SECONDARY RESEARCH

- PRIMARY RESEARCH

- SUBJECT-MATTER EXPERTS’ ADVICE

- QUALITY CHECKS

- FINAL REVIEW

- DATA TRIANGULATION

- BOTTOM-UP APPROACH

- TOP-DOWN APPROACH

- RESEARCH FLOW

- DATA SOURCES

- DATA MINING

- EXECUTIVE SUMMARY

- MARKET OVERVIEW

- GARDEN SEEDS MARKET OUTLOOK

- MARKET DRIVERS

- MARKET RESTRAINTS

- MARKET OPPORTUNITIES

- IMPACT OF COVID-19 ON MICRO PORE CARBON BLOCK MARKET

- PORTER’S FIVE FORCES MODEL

- THREAT FROM NEW ENTRANTS

- THREAT FROM SUBSTITUTES

- BARGAINING POWER OF SUPPLIERS

- BARGAINING POWER OF CUSTOMERS

- DEGREE OF COMPETITION

- INDUSTRY VALUE CHAIN ANALYSIS

- GARDEN SEEDS MARKET OUTLOOK

- GLOBAL MICRO PORE CARBON BLOCK MARKET BY TYPE, 2020-2030, (USD BILLION) (THOUSAND UNITS)

- AVERAGE PORE SIZE 0.3 µM-0.5 µM

- AVERAGE PORE SIZE IS LESS THAN 0.3 µM

- GLOBAL MICRO PORE CARBON BLOCK MARKET BY APPLICATION, 2020-2030, (USD BILLION) (THOUSAND UNITS)

- BLAST FURNACE

- PICKLING TANK

- PLATING BATH

- OTHER

- GLOBAL MICRO PORE CARBON BLOCK MARKET BY REGION, 2020-2030, (USD BILLION) (THOUSAND UNITS)

- NORTH AMERICA

- US

- CANADA

- MEXICO

- SOUTH AMERICA

- BRAZIL

- ARGENTINA

- COLOMBIA

- REST OF SOUTH AMERICA

- EUROPE

- GERMANY

- UK

- FRANCE

- ITALY

- SPAIN

- RUSSIA

- REST OF EUROPE

- ASIA PACIFIC

- INDIA

- CHINA

- JAPAN

- SOUTH KOREA

- AUSTRALIA

- SOUTH-EAST ASIA

- REST OF ASIA PACIFIC

- MIDDLE EAST AND AFRICA

- UAE

- SAUDI ARABIA

- SOUTH AFRICA

- REST OF MIDDLE EAST AND AFRICA

- NORTH AMERICA

- COMPANY PROFILES*

(BUSINESS OVERVIEW, COMPANY SNAPSHOT, PRODUCTS OFFERED, RECENT DEVELOPMENTS)

- KURARAY CO., LTD

- CABOT CORPORATION

- CALGON CARBON CORPORATION

- HAYCARB PLC

- OSAKA GAS CHEMICALS CO., LTD

- CARBON ACTIVATED CORPORATION

- ADA CARBON SOLUTIONS

- CECA

- DONAU CARBON CORPORATION

- INGEVITY CORPORATION

- CLARIMEX GROUP

- ACTIVATED CARBON TECHNOLOGIES

- CARBON LINK CORPORATION

- CARBON RESOURCES LLC

- WESTWATER ENTERPRISES

- L. FILTER

- CARBOTECH AC GMBH

- OXBOW ACTIVATED CARBON

*THE COMPANY LIST IS INDICATIVE

LIST OF TABLES

TABLE 1 GLOBAL MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 2 GLOBAL MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 3 GLOBAL MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 4 GLOBAL MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 5 GLOBAL MICRO PORE CARBON BLOCK MARKET BY REGION (USD BILLION) 2020-2030

TABLE 6 GLOBAL MICRO PORE CARBON BLOCK MARKET BY REGION (THOUSAND UNITS) 2020-2030

TABLE 7 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (USD BILLION) 2020-2030

TABLE 8 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (THOUSAND UNITS) 2020-2030

TABLE 9 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 10 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 11 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 12 NORTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 13 US MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 14 US MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 15 US MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 16 US MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 17 CANADA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 18 CANADA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 19 CANADA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 20 CANADA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 21 MEXICO MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 22 MEXICO MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 23 MEXICO MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 24 MEXICO MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 25 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (USD BILLION) 2020-2030

TABLE 26 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (THOUSAND UNITS) 2020-2030

TABLE 27 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 28 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 29 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 30 SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 31 BRAZIL MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 32 BRAZIL MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 33 BRAZIL MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 34 BRAZIL MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 35 ARGENTINA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 36 ARGENTINA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 37 ARGENTINA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 38 ARGENTINA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 39 COLOMBIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 40 COLOMBIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 41 COLOMBIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 42 COLOMBIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 43 REST OF SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 44 REST OF SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 45 REST OF SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 46 REST OF SOUTH AMERICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 47 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY COUNTRY (USD BILLION) 2020-2030

TABLE 48 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY COUNTRY (THOUSAND UNITS) 2020-2030

TABLE 49 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 50 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 51 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 52 ASIA-PACIFIC MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 53 INDIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 54 INDIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 55 INDIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 56 INDIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 57 CHINA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 58 CHINA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 59 CHINA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 60 CHINA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 61 JAPAN MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 62 JAPAN MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 63 JAPAN MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 64 JAPAN MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 65 SOUTH KOREA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 66 SOUTH KOREA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 67 SOUTH KOREA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 68 SOUTH KOREA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 69 AUSTRALIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 70 AUSTRALIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 71 AUSTRALIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 72 AUSTRALIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 73 SOUTH-EAST ASIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 74 SOUTH-EAST ASIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 75 SOUTH-EAST ASIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 76 SOUTH-EAST ASIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 77 REST OF ASIA PACIFIC MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 78 REST OF ASIA PACIFIC MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 79 REST OF ASIA PACIFIC MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 80 REST OF ASIA PACIFIC MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 81 EUROPE MICRO PORE CARBON BLOCK MARKET BY COUNTRY (USD BILLION) 2020-2030

TABLE 82 EUROPE MICRO PORE CARBON BLOCK MARKET BY COUNTRY (THOUSAND UNITS) 2020-2030

TABLE 83 EUROPE MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 84 EUROPE MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 85 EUROPE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 86 EUROPE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 87 GERMANY MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 88 GERMANY MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 89 GERMANY MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 90 GERMANY MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 91 UK MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 92 UK MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 93 UK MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 94 UK MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 95 FRANCE MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 96 FRANCE MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 97 FRANCE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 98 FRANCE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 99 ITALY MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 100 ITALY MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 101 ITALY MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 102 ITALY MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 103 SPAIN MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 104 SPAIN MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 105 SPAIN MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 106 SPAIN MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 107 RUSSIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 108 RUSSIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 109 RUSSIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 110 RUSSIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 111 REST OF EUROPE MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 112 REST OF EUROPE MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 113 REST OF EUROPE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 114 REST OF EUROPE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 115 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (USD BILLION) 2020-2030

TABLE 116 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY COUNTRY (THOUSAND UNITS) 2020-2030

TABLE 117 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 118 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 119 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 120 MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 121 UAE MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 122 UAE MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 123 UAE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 124 UAE MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 125 SAUDI ARABIA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 126 SAUDI ARABIA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 127 SAUDI ARABIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 128 SAUDI ARABIA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 129 SOUTH AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 130 SOUTH AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 131 SOUTH AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 132 SOUTH AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

TABLE 133 REST OF MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (USD BILLION) 2020-2030

TABLE 134 REST OF MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY TYPE (THOUSAND UNITS) 2020-2030

TABLE 135 REST OF MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (USD BILLION) 2020-2030

TABLE 136 REST OF MIDDLE EAST AND AFRICA MICRO PORE CARBON BLOCK MARKET BY APPLICATION (THOUSAND UNITS) 2020-2030

LIST OF FIGURES

FIGURE 1 MARKET DYNAMICS

FIGURE 2 MARKET SEGMENTATION

FIGURE 3 REPORT TIMELINES: YEARS CONSIDERED

FIGURE 4 DATA TRIANGULATION

FIGURE 5 BOTTOM-UP APPROACH

FIGURE 6 TOP-DOWN APPROACH

FIGURE 7 RESEARCH FLOW

FIGURE 8 GLOBAL MICRO PORE CARBON BLOCK MARKET BY TYPE USD BILLION, 2020-2030

FIGURE 9 GLOBAL MICRO PORE CARBON BLOCK MARKET BY APPLICATION, USD BILLION, 2020-2030

FIGURE 10 GLOBAL MICRO PORE CARBON BLOCK MARKET BY REGION, USD BILLION, 2020-2030

FIGURE 11 PORTER’S FIVE FORCES MODEL

FIGURE 12 GLOBAL MICRO PORE CARBON BLOCK MARKET BY TYPE, USD BILLION 2022

FIGURE 13 GLOBAL MICRO PORE CARBON BLOCK MARKET BY APPLICATION, USD BILLION 2022

FIGURE 14 GLOBAL MICRO PORE CARBON BLOCK MARKET BY REGION, USD BILLION 2022

FIGURE 15 MARKET SHARE ANALYSIS

FIGURE 16 KURARAY CO., LTD: COMPANY SNAPSHOT

FIGURE 17 CABOT CORPORATION: COMPANY SNAPSHOT

FIGURE 18 CALGON CARBON CORPORATION: COMPANY SNAPSHOT

FIGURE 19 HAYCARB PLC: COMPANY SNAPSHOT

FIGURE 20 OSAKA GAS CHEMICALS CO., LTD: COMPANY SNAPSHOT

FIGURE 21 CARBON ACTIVATED CORPORATION: COMPANY SNAPSHOT

FIGURE 22 ADA CARBON SOLUTIONS: COMPANY SNAPSHOT

FIGURE 23 CECA: COMPANY SNAPSHOT

FIGURE 24 DONAU CARBON CORPORATION: COMPANY SNAPSHOT

FIGURE 25 INGEVITY CORPORATION: COMPANY SNAPSHOT

FIGURE 26 CLARIMEX GROUP: COMPANY SNAPSHOT

FIGURE 27 ACTIVATED CARBON TECHNOLOGIES: COMPANY SNAPSHOT

FIGURE 28 CARBON LINK CORPORATION: COMPANY SNAPSHOT

FIGURE 29 CARBON RESOURCES LLC: COMPANY SNAPSHOT

FIGURE 30 WESTWATER ENTERPRISES: COMPANY SNAPSHOT

FIGURE 31 A.L. FILTER: COMPANY SNAPSHOT

FIGURE 32 CARBOTECH AC GMBH: COMPANY SNAPSHOT

FIGURE 33 OXBOW ACTIVATED CARBON: COMPANY SNAPSHOT

DOWNLOAD FREE SAMPLE REPORT

License Type

SPEAK WITH OUR ANALYST

Want to know more about the report or any specific requirement?

WANT TO CUSTOMIZE THE REPORT?

Our Clients Speak

We asked them to research ‘ Equipment market’ all over the world, and their whole arrangement was helpful to us. thehealthanalytics.com insightful analysis and reports contributed to our current analysis and in creating a future strategy. Besides, the te

Yosuke Mitsui

Senior Associate Construction Equipment Sales & Marketing

We asked them to research ‘Equipment market’ all over the world, and their whole arrangement was helpful to us. thehealthanalytics.com insightful analysis and reports contributed to our current analysis and in creating a future strategy. Besides, the te